Sunday, March 31, 2013

Airplanes are Flocking

Blessed Easter to all!

We returned to the boat after church services, and while Al attempted to nap, I had fun watching the airplanes come and go! There has been MUCH activity all around with the nice weather, with an increase in soaring eagles, the dock traffic of people, dogs and boats, and the number of seaplane flights.

This plane did a pre-landing flyover, and then turned to come in for a landing. It is 'The Evening Plane'!

One day last week, we saw the greatest number of seaplanes in the harbor that WE have ever seen. One was my favorite -- the only one I learned to differentiate, because her tail numbers seemed to spell out 'Nooka' to me. So that's what I called her.

That day I learned that N900KA is actually called Maggie. And she spent a good part of the day getting a tune-up at the seaplane dock. And she was the head of the 'flock'.

She had lots of company! Here's a shot showing FOUR seaplanes in one shot:

Read a short article here: http://www.airlinepilotforums.com/archive/index.php/t-14856.html mentioning both Maggie and the current 'Evening Plane'.

We returned to the boat after church services, and while Al attempted to nap, I had fun watching the airplanes come and go! There has been MUCH activity all around with the nice weather, with an increase in soaring eagles, the dock traffic of people, dogs and boats, and the number of seaplane flights.

This plane did a pre-landing flyover, and then turned to come in for a landing. It is 'The Evening Plane'!

One day last week, we saw the greatest number of seaplanes in the harbor that WE have ever seen. One was my favorite -- the only one I learned to differentiate, because her tail numbers seemed to spell out 'Nooka' to me. So that's what I called her.

That day I learned that N900KA is actually called Maggie. And she spent a good part of the day getting a tune-up at the seaplane dock. And she was the head of the 'flock'.

She had lots of company! Here's a shot showing FOUR seaplanes in one shot:

Read a short article here: http://www.airlinepilotforums.com/archive/index.php/t-14856.html mentioning both Maggie and the current 'Evening Plane'.

Thursday, March 28, 2013

Short-timer

This morning Kisti and I planned out our departure based on the Tides. We want to hit the Slack (or a bit of flood) on Guemes Channel (err - more correctly: AVOID the ebb which will be 3kts on the noise April 1st..)

With slack being 1646PDT we figure will depart Friday Harbor around 1:30pm or so.

A night in Anacortes ("STARBUCKS" says Kristi, "CHINESE FOOD" says I), a work-work phone call Tuesday morning - Fuel dock (we figure we used around 250gal over the winter for heating), and then off to Cypress Island for the night. Working our way North into Canada over the next few days.

Back in the Water again.

With slack being 1646PDT we figure will depart Friday Harbor around 1:30pm or so.

A night in Anacortes ("STARBUCKS" says Kristi, "CHINESE FOOD" says I), a work-work phone call Tuesday morning - Fuel dock (we figure we used around 250gal over the winter for heating), and then off to Cypress Island for the night. Working our way North into Canada over the next few days.

Back in the Water again.

Monday, March 25, 2013

A Girl Post. (OK. *sigh* ... An Old Lady Post)

Several things have been making me feel old lately.

I used to tell my kids that 'Parenthood looks different from the other side!' Well, now I'm learning that Aging looks different from the other side as well!

Cataract surgery has been a blessing for my distance vision, but it has changed my near vision, a LOT. Now, anything closer than arms-length distance is not clear.

This makes applying cosmetics a bit of a 'hit or miss' prospect. You've all see the 'little old ladies' with the crookedly drawn on eyebrows? Or the uneven eyeliner? And have you thought, like me, 'Can't they SEE that???' Well, now I know, the answer is, 'NO! They can't!'

We even bought a magnifying mirror, which helped.

But I still could not get a CLOSE view like I used to be able to with my myopic eyes. I used to say I had to put my nose on the mirror to see what I was doing. That doesn't work any more.

However, a few days after Al took this picture for the post I was considering, we went to the drug store for something else, and at the checkout there was a lighted compact, with 1X and 10X mirrors! YAY! NOW I can see what I've been missing.... OMG, I need to tweeze my eyebrows!

I used to tell my kids that 'Parenthood looks different from the other side!' Well, now I'm learning that Aging looks different from the other side as well!

Cataract surgery has been a blessing for my distance vision, but it has changed my near vision, a LOT. Now, anything closer than arms-length distance is not clear.

This makes applying cosmetics a bit of a 'hit or miss' prospect. You've all see the 'little old ladies' with the crookedly drawn on eyebrows? Or the uneven eyeliner? And have you thought, like me, 'Can't they SEE that???' Well, now I know, the answer is, 'NO! They can't!'

We even bought a magnifying mirror, which helped.

But I still could not get a CLOSE view like I used to be able to with my myopic eyes. I used to say I had to put my nose on the mirror to see what I was doing. That doesn't work any more.

However, a few days after Al took this picture for the post I was considering, we went to the drug store for something else, and at the checkout there was a lighted compact, with 1X and 10X mirrors! YAY! NOW I can see what I've been missing.... OMG, I need to tweeze my eyebrows!

Thursday, March 21, 2013

20% off Front Panel Express till June 30th.

If anyone is thinking about using the company I used for our custom panels on Viking Star, Front Panel Express sent me this eCoupon. You can get 20% your 1st order. Valid till June 30th.

Monday, March 18, 2013

Arduino based Generator Controller and Regulator installed.

Today I completed the installation of the Arduino based Generator Controller / Alternator Regulator, and I will say it is looking sharp.

Just in time for our departure at the end of the month. Now starting the generator is just a matter of 'pressing a button'. It starts, ramp up slowly, does the 3-step regulation things, and slowly ramps down before stopping. But more important, it maximizes every minute of run time to get the most power out of the engine possible.

Tonight after I got the panel installed I did a 'test run', turning the generator on and off. Even Kristi stopped and gave it an admiring look (Well, that is MY story and I am sticking with it)

Just in time for our departure at the end of the month. Now starting the generator is just a matter of 'pressing a button'. It starts, ramp up slowly, does the 3-step regulation things, and slowly ramps down before stopping. But more important, it maximizes every minute of run time to get the most power out of the engine possible.

Tonight after I got the panel installed I did a 'test run', turning the generator on and off. Even Kristi stopped and gave it an admiring look (Well, that is MY story and I am sticking with it)

Wednesday, March 13, 2013

Addressing a Major Flaw in Water-maker Flushing . .

Last fall I repickled the water-maker in preparation for the winter. While doing so I noticed the output was down a little. Part of that might be because it was late fall, and the water was colder. But in Googling it seems the likely cause might also be some type of fouling in the RO membranes, either mineral or biological. And given prior usage, Biological is most likely. This is, after all, one of the key reasons one pickles the system when not in use. Digging deeper turned up cleaning procedures (using Lye) and if possible warm water. I will do this later this year. But, there is a bit more here. . . .

Upon closer inspection I also noticed signs of bio-growth on the flow gauges Just a little in the corners. And the bottom of the production tubes had a bit of brown to them. It got me thinking - the way we boaters 'pickle' our system is to circulate preservation through the membranes. We even have two turn-outs to simplify this (See Flush in and Flush Out in the diagram below) . It is a very common to see this type of setup for small water-makers - heck some suppliers even sell special pre-filters that contain the needed chemicals to make it even simpler.

.But it got me thinking - this all-to-common procedure has a MAJOR lacking - it only treats the sea-water side of the system... There is no way treatment will make it across the membrane into the produce side. And I think that might be part of what has caused our reduced output - Bio fouling in the fresh water side.

So I made a simply modification to allow for treatment of the production side, ala:

Note the addition of "FW - Flush In" and the two valves. To use, I will connect the flushing pump up to "FW Flush-in" open the two small valves and place the "RO Water Out" hose back into the circulation bucket. That way we pass treatment water through the whole fresh water side of the system. Combine it with the Salt Water side flush and we will have a well treated system!

To make this change removing the pressure tube end caps, drilling out the output hole (Or remove plugs, depending on your system), and installed the new valves and hose .

As this is in the production side (fresh water side) pressure will be very low and plastic components can be used. I added independent valves so I can select each membrane for flushing and make sure both get a good dose.

With this change I can treat teat the Salt Water side, and then treat the Fresh Water side. It seems an obvious lacking in most designs, and I am looking forward to cleaning the system this spring - both sides. And a protection of ALL PARTS of the system when it is placed into storage next fall.

(And if you want to see more about Viking Star's Water-maker, click on the Watermaker link to the right)

Upon closer inspection I also noticed signs of bio-growth on the flow gauges Just a little in the corners. And the bottom of the production tubes had a bit of brown to them. It got me thinking - the way we boaters 'pickle' our system is to circulate preservation through the membranes. We even have two turn-outs to simplify this (See Flush in and Flush Out in the diagram below) . It is a very common to see this type of setup for small water-makers - heck some suppliers even sell special pre-filters that contain the needed chemicals to make it even simpler.

.But it got me thinking - this all-to-common procedure has a MAJOR lacking - it only treats the sea-water side of the system... There is no way treatment will make it across the membrane into the produce side. And I think that might be part of what has caused our reduced output - Bio fouling in the fresh water side.

So I made a simply modification to allow for treatment of the production side, ala:

|

| Improved design with Fresh Water side Flush Note also relocated heater-exchanger to pre-heat water |

To make this change removing the pressure tube end caps, drilling out the output hole (Or remove plugs, depending on your system), and installed the new valves and hose .

|

| Original installation, note production side(hole in center of cap) is not connected on this end of the pressure tubes. |

|

| And here is why, the hole is tapped, but not drilled through. |

|

| Careful to drill out |

|

| And add individual valves. (Note the Lye-In-Waiting in the background!) |

|

| And the rest of the parts needed to complete a "Fresh Water Flush" |

With this change I can treat teat the Salt Water side, and then treat the Fresh Water side. It seems an obvious lacking in most designs, and I am looking forward to cleaning the system this spring - both sides. And a protection of ALL PARTS of the system when it is placed into storage next fall.

(And if you want to see more about Viking Star's Water-maker, click on the Watermaker link to the right)

Saturday, March 9, 2013

A Less 'Technical' Post

Yikes!

I (Kristi) just attempted an edit of Al's Summary and Conclusion post. I think it's more than I can face to even look at the previous 'Magnum/Splendide' posts, so you'll get the 'totally Al' effect there.

I surely DO appreciate what a smart guy he is, though!

But for a bit of relief for you folks that are a bit more like me....

This is one of the last sunsets before we begin Daylight Savings Time (this was Thursday evening, I believe). It is rather rare for the water to be SO calm that it reflects like this.

I (Kristi) just attempted an edit of Al's Summary and Conclusion post. I think it's more than I can face to even look at the previous 'Magnum/Splendide' posts, so you'll get the 'totally Al' effect there.

I surely DO appreciate what a smart guy he is, though!

But for a bit of relief for you folks that are a bit more like me....

|

| A Peaceful Evening |

This is one of the last sunsets before we begin Daylight Savings Time (this was Thursday evening, I believe). It is rather rare for the water to be SO calm that it reflects like this.

We have enjoyed February and what we've had of March so far here in Friday Harbor! (Last year we left in early February and went to Seattle, which was very grey and wet). It seems the town is waking up and stretching -- more and more activity and people as the weather gets nicer, especially on a sunny weekend!

But the nice weather and increased activity around us makes Al itchy to get going. Soon. The end of the month is coming.

And on another story...

Just so you know I am doing something other then playing with O'Scopes, Caps and Inverters - here is a photo of the mocked-up 'Control Panel' for the Arduino generator regulator / control project. I snuck-in a few alarm indicators (High water alarms, mains overheating) to the right.

|

| Mock up of control panel |

I use a company called Front Panel Express (www.frontpanelexpress.com/) to make up small panels like this. They have a downloadable CAD tool that is simple to use. Then just upload it and a week or so later you get your panel! Can even print out a sample in 1-1 scale (that is what you see above). So Nice.

The only down side is their prices have gone up a LOT over the past few years. This panel comes in at around $90 - - - But I already have several others of like look, so need to keep the trend going.

Hum - guess if I went with that Key-Fob idea I could skip the whole remote panel!

Today is Project Day. Last night made a list of things to do before leaving port at the end of the month. Almost 30 items - so guess I need to get on it.

Summary and Conclusion: Compatibility Issue Between MS2000 inverter and Splendide 2100XC Washer/Dryer

OK, This has been an interesting road to travel down. One I had totally not expected to have to travel, but I think I am at the end. If you have stumbled into some of the other posts, or want to see more details, just look back over the last week or so. But, with this post I am bringing things to a conclusion.

Short and Sweet:

Skip to 'The Solution' below for the quick answer, read on for the eye-glazing details.

==================================================================

Here is What I Know (Have seen with my own eyes):

Here is What I Have Been Told (And the sources seem to me as credible):

Here is What I Suspect (Likely true, but do not have any complete supportive information)

Here is What I Conclude (Based on the above, plus other research and data collection)

Background: Real Power vs. Reactive Power. In the Nice World (being DC world) all is simple. Amps are Amps, Volts are Volts and Watts are Volts * Amps. If something needs to get done, apply some Volts and send some Amps and energy (in the form of Watts) is delivered. In the Complex World (AC World - and yes I am totally ignoring all the issues a DC system can have) Amps are Amps, and Volts are Volts, but Watts are not always Watts... See, it all comes back to High School Math (why it is all the gnarly issues always come back to High School Math???) In the AC world we need to not only look at Amps and Volts, but their phase relationship Here is an example of a well behaved AC system, where the Volts (top trace) and the Amps (bottom trace) are all in step and symmetrical:

The above is an example of energy being delivered in a way referred to as Real Power by the Power Company folks. In this example a space heater, a pure resistive load, is being powered. Now, look at this example:

The Voltage still looks like a Sine wave (as we want), but the Current trace (the lower trace) is all over the map. What is going on here? This is an example of a complex load being driven -- in this case the Splendide washer/dryer. And it consists of two major components:

Of specific interest here is the wild squiggles. Not that they are squiggles (though that is interesting on its own), but that they are not lined up with the peak of the Voltage waveform. The squiggle current draw occurs before the peak of the voltage. In fact, this is a prime example of an Inductive Load, it occurs 90o out of phase with the Voltage and is what is know as Reactive Power. It is the direct result of an inductive load being powered (the drum motor in this case), is well know in the Power Company world, and is a major headache for them: http://en.wikipedia.org/wiki/AC_power

This out-of-phase current demand is summarized in a value called Power Factor. If everything is aligned, as in the 1st photo, the PF is known as 1. Anything less than 1 actually causes inefficiency and waste. In fact, the ENERGY STAR specifications often call for corrected Power Factors and require the load waveforms to look more like that shown in the 1st picture. But it costs money to add in PF correction. And when in a house with the MASSIVE AC power distribution (think Bonneville Dam and such) system supporting you, poor PF is really never noticed.

So what? Well, in my small world this became a major headache - because when this less than ideal PF load is being served by my relatively small inverter, the inverter needs to try and keep up with things. And it can not depend on 100,000's of tons of concrete and steel to do so. In my case, when driving this complex load, the Magnum inverter had a hard time keeping up and this is what I got:

See how the Voltage waveform now has a kind of hitch in it as it raises (top trace, left hand side)? And notice how the current being delivered no longer had the wild squiggles on the left. What is happening here is the Magnum inverter is not able to keep up with the demands of the Splendide washer/dryer. It can not supply that large out-of-phase inductive current draw we noted in the 2nd photo, and it can not keep the voltage nice and clean. It is struggling here - and as a result the washer/dryer starts misbehaving because it is not getting the reactive power it needs, the motor movement becomes jerky, the lights start flashing, things start clicking. It is a mess...

And a side note: This is also why some people complain their battery charger only delivers 60A while running from the Generator, but can do 100A when plugged into shore power. PF and the ability of the generator to support those less than ideal loads. (Should point out some inverter/chargers do have PF correcting in them - including the Magnum unit! But that is only when it is running as a charger. . . .)

Where is the 'Fault'? I would say both. The Splendide is sold into the Mobile market, and as such should take better care to design in some level of PF correction. Being a 'Poor Neighbor' when plugged into shore power is not noticeable due to the massive capabilities of the land-based AC power distribution system. But being that same poor neighbor in our small isolated world is -- well -- just being a poor neighbor. The Magnum line of inverters are from designers with a long history and experience in the field. Given it is clear that it is possible to design inverters with the capability to better support poor PF loads - witness the Xantrex ProSine 2000, the inverter inside the Honda 2000, generator, reportably Victron inverters, and even the Chinese inverters, I would have expected the Magnum to be better able to handle this complex load. This is perhaps my biggest surprise and, to be honest, disappointment.

What about OutBack inverters? Well, I have no idea. I had only one chance to look at an Outback on another boat, but just did not put the effort into figuring out how to move our boats near each other, plug in the Splendide into his boat and take measurements And no one from the T&T world has commented on the combination Also, the Splendide support folks do not seem to run across the Outback inverters often. (they mostly see Magnum and Xantrex, and mostly in high end Motor Homes!)

Resolution: Addressing and correcting inductive Reactive Power is a well know issue in AC Power Distribution systems. As almost exclusively reactive loads tend to show inductive properties the addition of capacitance to counteract is very common (Capacitance and Inductance are on the opposite ends of current off-setting). In fact, if one looks at AC Power distribution sub-stations you will see a wide array of Corrective Capacitors - they are typically semi-trailer sized units. And power companies charge factories extra if they themselves do not take steps to clean up their PF , typically through the addition of capacitors. But a key here is how to get exactly the right balance, as too much (over-correction) can bring its own issues. Lots of $$$ go into that problem, and solutions range from switched banks of capacitors to using other approaches as well. In the Big Boy space, this is a Big Boy topic.

For my issue on Viking Star, research has pointed to the addition of a 50uF capacitor to help address the Inductive part of the Splendide load. And here is what we get:

Notice how the voltage waveform has lost is kink, and looks more like a nice Sine wave. And notice also we are now able to supply the inductive current (that peak in the lower trace on the far left side of the screen) as needed by the washer motor. What is happening here is the Capacitor is saving up energy and releasing it when needed by the motor. Thereby relieving the Magnum of that responsibility. BTW: the kind of flat-top on the voltage waveform is another issue, for another day :-)

But a word of caution: because this problem only presents itself while running the washer/dryer, and there is always a risk of over-correction, I have placed the capacitor and the Splendide on an on/off switch. So the washer and the cap are only 'connected' when needed. And there is a side benefit! We had noticed the power saver sampling of our Xantrex inverter would wake up the Splendide - causing it to flash its LEDs. It did this every 30 seconds or so. Given our unit is located in the aft stateroom this is something we just grew to accept while trying to go to sleep. But with this new ON/Off switch we have no blinking LEDs!

I have also added a slow-blow fuse to the 50uF cap. Here I got a bit of controversy from some knowledgeable folks, some saying it is not really needed. But in my independent research, over-correction is a real issue, and it manifests itself in extreme cases by the system entering a resonance state. Given the Magnum is based in transformer technology (as opposed to pure PWM switching ala the Xantrex's ProSine) there IS a LC present between the 50uF cap and the Magnum inverter and hence a resonance state is possible. I was cautioned by one reviewer that some of my wave form captures had an early indication of such. A system that enters such a state will show large currents going back and forth to the Cap. Very large currents, in the real world that can cause issues like overheating of wires, tripping of breakers, etc. So, I do suggest the addition of a fuse. It should blow if a major resonance state presents itself.

==================================================================

The Solution: Ok, enough. Here is what I have for the solution. Adding a 50uF Motor Run to counteract the inductive load from the Splendide. Caution: Do make sure to use a RUN cap, not a Start Cap as the Start ones are designed to be used only for a few seconds.

Do note the part numbers shown are just reference -- any brand of Motor Run cap can be used, as well as fuse holders, etc. Just make sure they are rated for AC voltage (370+ on the cap, and 240+ on the fuse and fuse holder - note those Blade fuses are only rated to 32v!).

An enhancement would be to add a small 120v panel light (e.g. Radio Shack 272-710) paralleled with the Fuse to indicate if the system had at some time entered resonance blowing the fuse. Or if one notices the Splendide acting up again, check the fuse. If this keeps up, try using a smaller value of Run Capacitor. Maybe a 25uF. (In my trials, 7uF did not fully address the problem 15uF seemed OK. 50uF cleaned it up, and is the value recommended by Magnum - so that is why I went with it).

Thank yous: Nothing like this happens in a vacuum. I want to thank T&T members for their input - online and off. And specifically Mark W. for his expertise in these areas as well as sending me test equipment and a range of motor run caps. It is specifically through my mailings with him that I have a good level of confidence in the assessment and the solution.

Both the Magnum and Splendide tech support units have been responsive and helpful. When our Xantrex failed I specifically looked for another company based in their reputation for after sales support, and this experience has shown I made a good choice in Magnum. And I spent over an hour talking with the Splendide support head - getting not only insight into this issue but hints for cleaning the XC2100 as well as how to reduce wrinkles Both of these companies could have simply said 'Not Our Problem' (there was, to be honest, some of that in their responses), but neither did. They reviewed my data and gave insightful comments and in the case of Magnum- engineering input and review of the solution.

There you go. More than you EVER wanted to know, but then - are not Boats just full of Learning Opportunities!

Short and Sweet:

- The Splendide XC2100 Washer/Dryer and the Magnum MS2000/MS2012 inverters do not play well together.

- Other small washer/dryers may also have an issue.

- Problem is a bit of both side's fault - with the cause a well know issue in AC Power systems.

- Problem can be corrected with addition of 50uF motor Run Cap

Skip to 'The Solution' below for the quick answer, read on for the eye-glazing details.

==================================================================

Here is What I Know (Have seen with my own eyes):

- We have an interaction between the Splendide XC2100 Washer/Dryer and the Magnum MS2000 inverter. This manifests itself during the Wash portion of the cycle, and is indicated by a jerky motion on the drum, the LEDs flashing on and off, and the door-lock solenoid clicking.

- This interaction can be easily reproduced, though seems to be somewhat dependent on the load being washed.

- We did not see this at any time over 2 years of operation using a Xantrex ProSine 2000 inverter.

Here is What I Have Been Told (And the sources seem to me as credible):

- This interaction has been seen before with the Magnum Inverter and Splendide washer/dryers.

- The interaction has been seen before with the Magnum Inverter and other brands of small washers (e.g. Bosch)

- This issue is NOT seen using some other brands of inverters, specifically the before mentioned Xantrex Prosine 2000, as well as the GoPower line of Chinese stand-alone inverters.

- Three T&T mailing list members have indicated no issues using the Victron line of Inverters

- Three T&T mailing list members have indicated problems with small washer/dryers and MS2000/MS2012 inverters. Two were solved via the Cap solution below, one did not - his was solved by changing out to a MS2812 inverter.

- Four T&T mailing list members have indicated no issues using the Magnum inverter, all of them were using an MS inverter (true Sine-wave) other then the MS2000 or MS2012. (Ala, a larger Magnum inverter).

Here is What I Suspect (Likely true, but do not have any complete supportive information)

- Many brands and models of these small washer/dryers have issues with the Magnum inverter as well as some other brands and models of Inverters, and even some small AC Generators.

- We have powered the Splendide using our Honda 2000 generator with no issues, but only a handful of times. (Next time I have the Honda gassed up I will put the scope to it and see what things look like)

Here is What I Conclude (Based on the above, plus other research and data collection)

- The Splendide XC2100 has little to no (likely no) PF (Power Factor) correction in its design. Likely other small size washer/dryers and stand alone washers have the same deficiency.

- The Magnum MS2000 / MS2012 inverters are unable to properly support poor PF loads.

Background: Real Power vs. Reactive Power. In the Nice World (being DC world) all is simple. Amps are Amps, Volts are Volts and Watts are Volts * Amps. If something needs to get done, apply some Volts and send some Amps and energy (in the form of Watts) is delivered. In the Complex World (AC World - and yes I am totally ignoring all the issues a DC system can have) Amps are Amps, and Volts are Volts, but Watts are not always Watts... See, it all comes back to High School Math (why it is all the gnarly issues always come back to High School Math???) In the AC world we need to not only look at Amps and Volts, but their phase relationship Here is an example of a well behaved AC system, where the Volts (top trace) and the Amps (bottom trace) are all in step and symmetrical:

|

| Nice well behaved. Voltage and Current traces are in step and very Sine looking. |

|

| Not so nice. . . Notice wild lower (current) trace |

- The spike aligned with the top of the Voltage Sinewave curve is from the internal 'electronics' power supply.

- The wild squiggles on the left are from the variable speed induction motor driving the washer drum.

Of specific interest here is the wild squiggles. Not that they are squiggles (though that is interesting on its own), but that they are not lined up with the peak of the Voltage waveform. The squiggle current draw occurs before the peak of the voltage. In fact, this is a prime example of an Inductive Load, it occurs 90o out of phase with the Voltage and is what is know as Reactive Power. It is the direct result of an inductive load being powered (the drum motor in this case), is well know in the Power Company world, and is a major headache for them: http://en.wikipedia.org/wiki/AC_power

This out-of-phase current demand is summarized in a value called Power Factor. If everything is aligned, as in the 1st photo, the PF is known as 1. Anything less than 1 actually causes inefficiency and waste. In fact, the ENERGY STAR specifications often call for corrected Power Factors and require the load waveforms to look more like that shown in the 1st picture. But it costs money to add in PF correction. And when in a house with the MASSIVE AC power distribution (think Bonneville Dam and such) system supporting you, poor PF is really never noticed.

So what? Well, in my small world this became a major headache - because when this less than ideal PF load is being served by my relatively small inverter, the inverter needs to try and keep up with things. And it can not depend on 100,000's of tons of concrete and steel to do so. In my case, when driving this complex load, the Magnum inverter had a hard time keeping up and this is what I got:

|

| Magnum unable to supply current demands of the Splendide |

See how the Voltage waveform now has a kind of hitch in it as it raises (top trace, left hand side)? And notice how the current being delivered no longer had the wild squiggles on the left. What is happening here is the Magnum inverter is not able to keep up with the demands of the Splendide washer/dryer. It can not supply that large out-of-phase inductive current draw we noted in the 2nd photo, and it can not keep the voltage nice and clean. It is struggling here - and as a result the washer/dryer starts misbehaving because it is not getting the reactive power it needs, the motor movement becomes jerky, the lights start flashing, things start clicking. It is a mess...

And a side note: This is also why some people complain their battery charger only delivers 60A while running from the Generator, but can do 100A when plugged into shore power. PF and the ability of the generator to support those less than ideal loads. (Should point out some inverter/chargers do have PF correcting in them - including the Magnum unit! But that is only when it is running as a charger. . . .)

Where is the 'Fault'? I would say both. The Splendide is sold into the Mobile market, and as such should take better care to design in some level of PF correction. Being a 'Poor Neighbor' when plugged into shore power is not noticeable due to the massive capabilities of the land-based AC power distribution system. But being that same poor neighbor in our small isolated world is -- well -- just being a poor neighbor. The Magnum line of inverters are from designers with a long history and experience in the field. Given it is clear that it is possible to design inverters with the capability to better support poor PF loads - witness the Xantrex ProSine 2000, the inverter inside the Honda 2000, generator, reportably Victron inverters, and even the Chinese inverters, I would have expected the Magnum to be better able to handle this complex load. This is perhaps my biggest surprise and, to be honest, disappointment.

What about OutBack inverters? Well, I have no idea. I had only one chance to look at an Outback on another boat, but just did not put the effort into figuring out how to move our boats near each other, plug in the Splendide into his boat and take measurements And no one from the T&T world has commented on the combination Also, the Splendide support folks do not seem to run across the Outback inverters often. (they mostly see Magnum and Xantrex, and mostly in high end Motor Homes!)

Resolution: Addressing and correcting inductive Reactive Power is a well know issue in AC Power Distribution systems. As almost exclusively reactive loads tend to show inductive properties the addition of capacitance to counteract is very common (Capacitance and Inductance are on the opposite ends of current off-setting). In fact, if one looks at AC Power distribution sub-stations you will see a wide array of Corrective Capacitors - they are typically semi-trailer sized units. And power companies charge factories extra if they themselves do not take steps to clean up their PF , typically through the addition of capacitors. But a key here is how to get exactly the right balance, as too much (over-correction) can bring its own issues. Lots of $$$ go into that problem, and solutions range from switched banks of capacitors to using other approaches as well. In the Big Boy space, this is a Big Boy topic.

For my issue on Viking Star, research has pointed to the addition of a 50uF capacitor to help address the Inductive part of the Splendide load. And here is what we get:

|

| 50uF Capacitor to the rescue! |

Notice how the voltage waveform has lost is kink, and looks more like a nice Sine wave. And notice also we are now able to supply the inductive current (that peak in the lower trace on the far left side of the screen) as needed by the washer motor. What is happening here is the Capacitor is saving up energy and releasing it when needed by the motor. Thereby relieving the Magnum of that responsibility. BTW: the kind of flat-top on the voltage waveform is another issue, for another day :-)

But a word of caution: because this problem only presents itself while running the washer/dryer, and there is always a risk of over-correction, I have placed the capacitor and the Splendide on an on/off switch. So the washer and the cap are only 'connected' when needed. And there is a side benefit! We had noticed the power saver sampling of our Xantrex inverter would wake up the Splendide - causing it to flash its LEDs. It did this every 30 seconds or so. Given our unit is located in the aft stateroom this is something we just grew to accept while trying to go to sleep. But with this new ON/Off switch we have no blinking LEDs!

I have also added a slow-blow fuse to the 50uF cap. Here I got a bit of controversy from some knowledgeable folks, some saying it is not really needed. But in my independent research, over-correction is a real issue, and it manifests itself in extreme cases by the system entering a resonance state. Given the Magnum is based in transformer technology (as opposed to pure PWM switching ala the Xantrex's ProSine) there IS a LC present between the 50uF cap and the Magnum inverter and hence a resonance state is possible. I was cautioned by one reviewer that some of my wave form captures had an early indication of such. A system that enters such a state will show large currents going back and forth to the Cap. Very large currents, in the real world that can cause issues like overheating of wires, tripping of breakers, etc. So, I do suggest the addition of a fuse. It should blow if a major resonance state presents itself.

==================================================================

The Solution: Ok, enough. Here is what I have for the solution. Adding a 50uF Motor Run to counteract the inductive load from the Splendide. Caution: Do make sure to use a RUN cap, not a Start Cap as the Start ones are designed to be used only for a few seconds.

|

| Solution to Magnum / Splendide incompatibility |

An enhancement would be to add a small 120v panel light (e.g. Radio Shack 272-710) paralleled with the Fuse to indicate if the system had at some time entered resonance blowing the fuse. Or if one notices the Splendide acting up again, check the fuse. If this keeps up, try using a smaller value of Run Capacitor. Maybe a 25uF. (In my trials, 7uF did not fully address the problem 15uF seemed OK. 50uF cleaned it up, and is the value recommended by Magnum - so that is why I went with it).

Thank yous: Nothing like this happens in a vacuum. I want to thank T&T members for their input - online and off. And specifically Mark W. for his expertise in these areas as well as sending me test equipment and a range of motor run caps. It is specifically through my mailings with him that I have a good level of confidence in the assessment and the solution.

Both the Magnum and Splendide tech support units have been responsive and helpful. When our Xantrex failed I specifically looked for another company based in their reputation for after sales support, and this experience has shown I made a good choice in Magnum. And I spent over an hour talking with the Splendide support head - getting not only insight into this issue but hints for cleaning the XC2100 as well as how to reduce wrinkles Both of these companies could have simply said 'Not Our Problem' (there was, to be honest, some of that in their responses), but neither did. They reviewed my data and gave insightful comments and in the case of Magnum- engineering input and review of the solution.

There you go. More than you EVER wanted to know, but then - are not Boats just full of Learning Opportunities!

Thursday, March 7, 2013

More Magnum / Splendide Photos - and Resolution?

We did another washer run this afternoon and I captured some additional photos. Played with placement of current probe vs. capacitor, and also tried to get samples of Shore power and then inverter power at ruffly the same time. And need to note: During this washer run we were unable to readily reproduce the failure - there was one point where it seemed to start to balk, but that was very brief unlike this morning when we could get it it fail right off the bat. Not sure what all that means, an noticing there was much less 'hooking' in the afternoon runs. Perhaps it depends on what all is being washed....

Ok, on to the photos:

A Couple of No-Cap samples, early in the wash cycle:

Next we have a series, all on the inverter, varying the location of a 55uF capacitor.

In this last photo notice the large current draw on the transition edges of the voltage - both raising and falling. This is the current the Splendide washer is asking for; measured at 5.7Ap for the raising edge.

And here is a set of the same situation of that last photo, Still measuring between the 55uf Cap and the Splendide - but this time using Shore Power as the source.

Can see a like current draw / a little different shape.

And for reference, here is a raw Shorepower w/o the cap snap during the same 'time period' as the rest of set #3:

OK, what does all this mean - to be honest I am not sure. I can clearly see that the 55uF cap removes all indication of hooking, and there is clearly some large current moving back and forth between the cap and the washer/dryer. Historically an indication of reactive power.

Going forward, I am going to order and add a 50uF cap near the Splendide - as Magnum suggested. Assuming the 'hooking' is an indication of the problem, the larger cap clearly takes care of that. And when the machine does fail, we can easily see a cause and effect between running with and w/o the cap. In terms of why this happened? For that am going to send these set of photos off the Magnum and Splendide and see what their thoughts are.

But for now based on a sample size of 1, along with some measurements, I am going to state the resolution for this compatibility issue is the 50uF motor run cap.

Ok, on to the photos:

A Couple of No-Cap samples, early in the wash cycle:

|

| Set #1 - Shore Power, No Cap |

|

| Set #1, Inverter, No Cap |

Early on the washer is not doing much, filling with water, maybe rotating things a bit. But kind of boring in terms to current draw..

And here is another set of no-cap samples, later in the cycle. The wash cycle is a bit more interesting now, the drum is being sloshed a bit, and water being pumped around. We were waiting for the machine to start balking.

|

| Set #2 - Shore Power, No Cap. |

|

| Set #2 - Inverter, No Cap |

Next we have a series, all on the inverter, varying the location of a 55uF capacitor.

|

| Set #3 - Inverter, 55uF Cap placed at Washer/dryer Current is being measured between the Inverter, and the Cap/washer/dryer. (This is where the Cap has been placed in all other trials) |

|

| Set #3 - Inverter, No Cap Notice No Hooking, just could not get a Hook this afternoon! |

|

| Set #3 - Inverter, 55uF Cap placed at inverter. (Current is being measured between the Inverter/Cap and the Washer/dryer) |

And here is a set of the same situation of that last photo, Still measuring between the 55uf Cap and the Splendide - but this time using Shore Power as the source.

|

| Set #3, Shore Power, 55uF cap placed at Shore power entrance point. (Current is being measured between Shore Power/Cap and the Washer/dryer) |

And for reference, here is a raw Shorepower w/o the cap snap during the same 'time period' as the rest of set #3:

|

| Set #3, Shore Power, No Cap. |

OK, what does all this mean - to be honest I am not sure. I can clearly see that the 55uF cap removes all indication of hooking, and there is clearly some large current moving back and forth between the cap and the washer/dryer. Historically an indication of reactive power.

Going forward, I am going to order and add a 50uF cap near the Splendide - as Magnum suggested. Assuming the 'hooking' is an indication of the problem, the larger cap clearly takes care of that. And when the machine does fail, we can easily see a cause and effect between running with and w/o the cap. In terms of why this happened? For that am going to send these set of photos off the Magnum and Splendide and see what their thoughts are.

But for now based on a sample size of 1, along with some measurements, I am going to state the resolution for this compatibility issue is the 50uF motor run cap.

Magnum / Splendide Photos

A T&T forum member loaned me a current transformer as well as a 55uF run cap. This morning I took a series of samples capturing current, voltage, and their phasing.

Voltage (the top trace) is as displayed (50v / div)

Current (bottom trace) translates into 1V = 10A, and do note the scale was changed between screens. To 'convert back':

- 0.2v --> 2A / div

- 0.5v --> 5A / div

- 1v --> 10A / div

Should also note that the current probe was placed between the Inverter and the Washer/dryer.

When Caps were added, they were placed at the washer/dryer - so the current probe was then between the Inverter and the Caps / Washer-dryer.

All measurements were take at 2mS / Div, and was triggered on the rising edge of the Voltage waveform.

First off, lets look at the washer when it is on shore power:

|

| Washer on Shore Power |

Nice looking sine wave, with the current spikes where one would expect them. I will note this was early in the washing cycle, perhaps things get more complex later on.

For fun, here is a capture of the Inverter powering a 750w space heater:

|

| Inverter powering 750w resistive load. |

Now lets look at an uncorrected (raw no Run Caps added) waveform from the inverter while powering the Splendide Washer / Dryer:

|

| Inverter, no correction. Notice start of hook. |

|

| Same, but accumulated waveform over 30 seconds or so. |

|

| Another ~30s block |

We can see the hooking that seems associated with the washer/dryer faulting. I do notice a bump in current just as the voltage starts to rise, and then it drops. Perhaps this workload is what is confusing things?

And here we have some waveforms with the addition of a 15uF motor run cap:

|

| Inverter + 15uF Run Cap |

|

| Inverter +15uF Run Cap, approx 30s accumulation |

In these photos we can see the current spike is more pronounced on the rising edge of the Voltage (30s accumulation capture) Do remember, the current probe is placed BETWEEN the inverter and the cap/washer-dryer.

And finally, here is the same but using the 55uF cap as opposed to the 15uF. (Will note, Magnum had recommended a 50uF cap as a solution):

|

| Inverter + 55uF cap |

|

| Inverter + 55uF cap, accumulated over approx 30s |

Clearly that leading edge current spikes noticeable And there seems to be a like spike on the falling edge as well, but perhaps not as large. On the accumulated capture, converting the 0.2v/div into amps this raising edge spike is 7.6Ap, I can not see the negative one so can not really measure it. But I estimate it to be 4.6Ap But no hook in the voltage! A bit flat topped perhaps, but no hook.

After this load of laundry finishes up I will run another series of measurements, I want to try and capture:

- More detail in the Rising Edge current spike.

- Additional shore power captures, esp during critical portion of washing cycle, not just the beginning.

- Sampling with the current transformer placed between the 55uF cap and the washer/dryer.

Saturday, March 2, 2013

More on Magnum MS2000 issues, and a potential solution

Note: Make sure to click here: mvVikingStar.blogspot.com/.../summery-and-conclusion-compatibility.html for the final post in this series.

=======================================================================

As reported here: http://mvvikingstar.blogspot.com/2013/02/compatibility-issue-between-ms2000.html we have been having problems with the new Magnum sinewave MS2000 inverter while powering the Splendide washer/dryer. Over the past couple of weeks I have been sharing Emails with support departments, taking some more measurements and trying to see if we can find a workaround. Based on my conversations and Emails with support personal as well as distributes of inverters, I can say today:

=======================================================================

As reported here: http://mvvikingstar.blogspot.com/2013/02/compatibility-issue-between-ms2000.html we have been having problems with the new Magnum sinewave MS2000 inverter while powering the Splendide washer/dryer. Over the past couple of weeks I have been sharing Emails with support departments, taking some more measurements and trying to see if we can find a workaround. Based on my conversations and Emails with support personal as well as distributes of inverters, I can say today:

- We clearly have an interaction between the Magnum MS2000 inverter and the Splendide Washer/dryer that renders the 'True Sinewave' anything but. (See waveforms below)

- It appears that other brands small washing machines and washer/dryers also have an issue with the Magnum products. One distributor I talked with installs dedicated Chinese sinewave inverters for this customers who want to run washer /dryers after having issues with the Magnum and Splendide as well as Bosch.

- We had no such issues when using the Prosine inverter, and I was told by support the Prosine seem to work well.

- Others from a Email list I subscribe to (3x total) have reported no issues with the Victron brand of inverters.

There needs only be one demonstration of a failure to prove a problem, while the absence of a problem does not prove anything. However, it does appear the Prosine inverter does not have this problem based on our experience and my conversations with tech support. While clearly the Magnum has an issue:

|

| Original noted FAILING waveform. 'Hooking' in red are suspect. |

I tried several approaches to moderate the waveform, ranging from unloaded induction motors (worked), to space heaters (also worked), a 40w light bulbs (did not work), hair irons (not work) and finally have settled on 15uF of 'motor run' capacitors located next to the washing machine. We have completed 5x runs now with no sign of an issue. Time will tell of this holds out. (and fyi: 7.7uF seemed promising, but the machine did show signs of struggling at one point during the 2nd trial run).

Someone is sending me some additional test equipment and I will be trying to gather more information - specifically current measurements and phasing. As I do I will continue to see what Magnum has to say (their current suggestion was 50uF of motor run caps, I have not found that many yet - and am working with 15uF). And when I get a more insightful answer, will post an update. Until then, it appears we have a 'workaround' that at least does not involve running the space heater at the same time (and wasting a tremendous amount of energy to boot).

The following are some additional waveforms I captured. Note that these were captured with the oscilloscope in an 'accumulate' mode - and show the range of waveforms over a long period of time. (as opposed to the one above which is a one time capture that I had to time just right to get.)

|

| FAILING waveform - only Washer/dryer. Note hooking. Washer/dryer repeatedly exhibited faulty motion with this waveform |

|

| Added 7.7uF run capacitor. Better - still some hooking. Washer/dryer stumbled slightly during 2nd trial run. |

|

| THIS is what it should look like! This is shore power. (And also the Magnum when not powering the washer/dryer!!!!???) |

After making some more measurements will likely adjust the workaround. But for now, we seem to have found something that will let us leave the dock for the summer. Will post another update when I have new information.

Friday, March 1, 2013

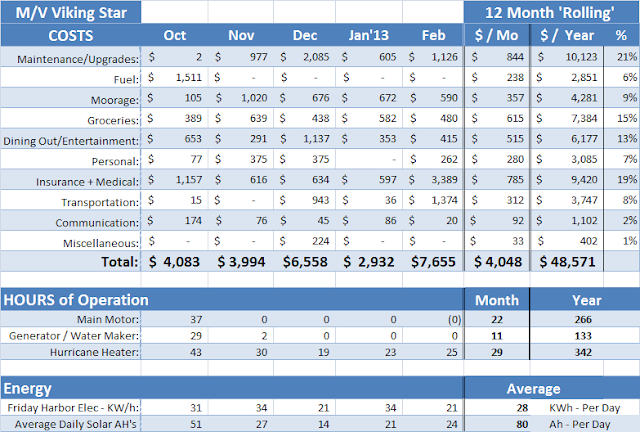

Cost to Cruise: Feb 2013

"....become tea-totaling vegetarians!" Was what Kristi thought was the answer to low cost cruising and she may be right. But to that we need to add blind ones who drink warm beer (oh wait, make that warm soy milk). Oh, and become hermits...

This month's costs are heavily impacted by three things:

This month's costs are heavily impacted by three things:

- Replacing TWO failed inverters (One died, one killed)

- Kristi's eye surgery (we are just seeing the start of that one showing up in the costs)

- Travel back East for Micah's graduation ceremony

And with those, we have an all-time high for a monthly cost. Now, we had been anticipating the eye surgery and putting aside funds. And we knew some travel was in the books for 2013. Inverters, well....

So, here it is:

Next month we intend to transfer to an international health insurance policy. Same level of coverage, about 1/4th the cost, though we will need to be out of the USA for 6mo's a year. Oh Well, tough life.

And Solar Panel output missed the mark by the largest % yet. In February we only produced an average of 24Ah/day, while modeling said we should have gotten 38 - or an error of -37%. I had the panels off-line for three days while futzing with the magnum/Splendide washer/dryer issue, but even accounting for that the actuals came in under the predicted. . .

And Solar Panel output missed the mark by the largest % yet. In February we only produced an average of 24Ah/day, while modeling said we should have gotten 38 - or an error of -37%. I had the panels off-line for three days while futzing with the magnum/Splendide washer/dryer issue, but even accounting for that the actuals came in under the predicted. . .

Hugs

This morning my facebook status reads 'In ten days I get to hug my son!' And after posting, I started thinking about the hugging in my life.

I grew up in a family where hugs were rare, and even rarer were the words 'I love you'. But don't get me wrong; we may not have SAID it, but we KNEW it. (There are many other ways to say 'I Love You' with out those three words)

I hope my kids knew, and know, that I love them, so much! Small children are so easy to hug. And my kids grew so quickly! Out of my lap and into teenagers, so easily embarrassed by affection. My girls are now mothers themselves, and their children -- my grandchildren -- receive the majority of my hugs. But I make sure to share a hug with my girls, usually as we are parting again.

Yes, it is more rare than I would like, and even a bit awkward sometimes. My 'baby' Micah is now a man, and at least 6-foot-two, and my head tucks under his chin.

Yes, all of my babies have grown up, but I still love to hug my kids.

Subscribe to:

Posts (Atom)